Aerospace, defense, and avionics power supply ATE test systems applications include functional testing of AC and DC power supplies, generator, and engine control units, as well as a wide range of associated electronics. Intepro’s knowledge and expertise in high-end power electronics test is unparalleled.

The table below lists a selection of the standard tests available for selection within the software.

User Manuals & Datasheets

Standard Library Tests Include

Output Performance

Input Characteristics

Regulation Test

Responce & Timing

Protection Test

Special Test

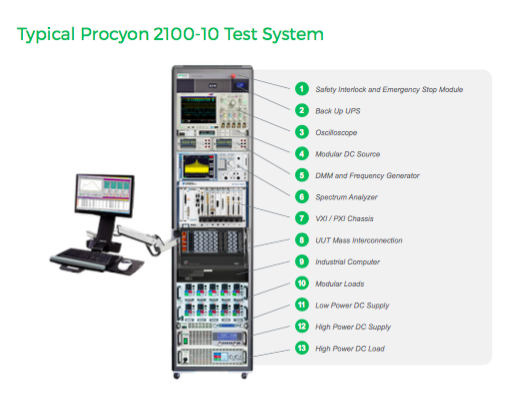

Typical Procyon 2100-10 Test System

Regenerative Load Technology

Project Management

Custom Solutions

Intepro provides turnkey, customizable solutions including test fixtures, Integrated Test Assemblies (ITA’s) and test programs for power supply test. Where high speed is required, Intepro has provided multiple test heads, optimized test programs from about a minute to a few seconds (PSU dependent). Improving power supply ATE.

All Intepro ATE test systems use PowerStar software. For more information click here.